1055 Hardened and Tempered Steel Strip

Hardened and tempered steel strip has comprehensive mechanical properties with good strength, hardness and toughness through hardening and tempering process. Tempering is a thermal process that strengthens steel strips through a controlled heating and cooling process.

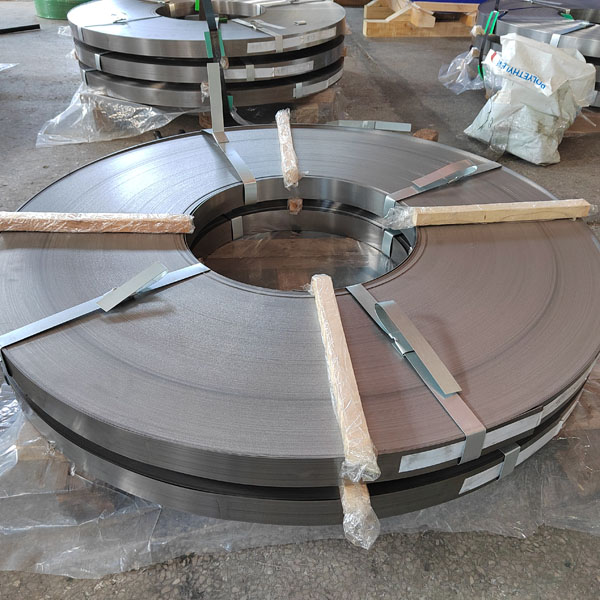

We focus on high dimensional accuracy and excellent surface quality and we have been producing high-quality steel strips for different industrial and technical purposes gaining experience to get best results in each market.

Chemical Composition:

Carbon: 0.52-0.60%

Silicon: 0.40% max

Manganese: 0.60-0.90%

Phosphorous: 0.030% max

Sulfur: 0.050% max

Supply Conditions:

Hardened and tempered

Thickness: 0.15-2.50mm

Width: 8.00-300.00mm

Hardness: 29-55HRC

Surface: nature, polished, blue, yellow, black

Edge: slit, sheared, square, rouned

Steel Applications:

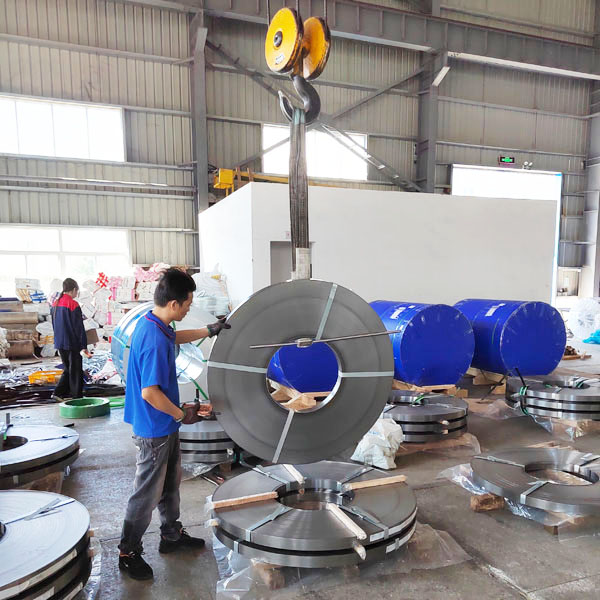

Our cold rolled hardened and tempered steel strips for saw blades, springs, are supplied in moderately smooth finish, free of lamination, pitting and scale on surfaces, they are the best starting point for high precision tools.

We also supply following materials in heat treatment conditions, and you can consult us for customized value requirements.

| Delivery condition (strip/coil/sheet) | Steel Grade | Annealed | Hardened and Tempered | ||

| Hardness<20HRC | Hardness 29-55HRC | ||||

| Thickness | Width | Thickness | Width | ||

| High carbon steel | C55S, C60S, C67S, C75S | 0.15-2.50mm | 8.00-600.00mm | 0.15-2.50mm | 8.00-300.00mm |

| Alloy spring steel | 51CrV4, 80CrV2 | 0.20-2.20mm | 8.00-180.00mm | 0.20-2.20mm | 8.00-180.00mm |

| Stainless spring steel | 3Cr13-6Cr13 | 0.20-2.50mm | 8.00-150.00mm | 0.20-2.50mm | 8.00-150.00mm |

| Finish | Nature, Polished (blue, yellow, white, grey-blue, black, bright) | ||||

| Tolerance | Thickness +/-0.03mm max; width +/-0.3mm max | ||||

| Tensile strength | 450-1850N/mm2 | ||||