Whipcheck Safety Sling for Hoses

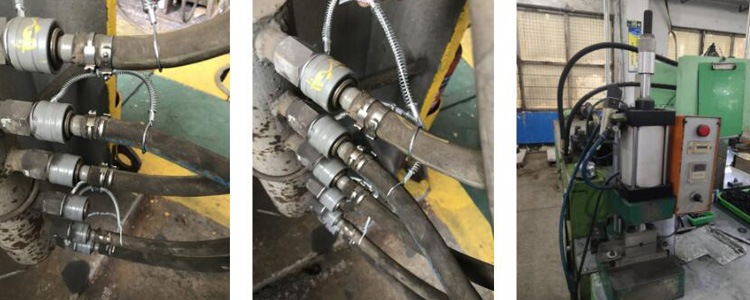

Whipchecks will be needed when working with high pressure and in low visibility situations. If a blast, bull, or other hose connection point was to become disconnected accidentally, the high pressure in the hose would cause the hose to whip or snap around and lash out at anything in its path.

There are 4 minimum locations where whipchecks should be installed:

• Air compressor to bull hose

• Inlet to blast machine

• Inlet and outlet connections

• Connection points along the hose

| Whipcheck Safety Sling | |||

| Part Number | Beschreibung | Material | Pressure Rating (PSI) |

| Standard | |||

| WCH1 | 1/8" Wire for Hose 1/2" to 1 1/4", 20 1/4" Long | Steel wire with Aluminium ferrules | 200 |

| WCH3 | 3/16" Wire for Hose 1/2" to 2", 28" Long | Steel wire with Aluminium ferrules | 200 |

| WCH2 | 1/4" Wire for Hose 1 1/2" to 3", 38" Long | Steel wire with Aluminium ferrules | 200 |

| WCH4 | 3/8" Wire for Hose 4", 44" Long | Steel wire with Aluminium ferrules | 200 |

| Copper Ferrules | |||

| WCH1-C | 1/8" Wire for Hose 1/2" to 1 1/4", 20 1/4" Long | Steel wire with Copper ferrules | 200 |

| WCH3-C | 3/16" Wire for Hose 1/2" to 2", 28" Long | Steel wire with Copper ferrules | 200 |

| WCH2-C | 1/4" Wire for Hose 1 1/2" to 3", 38" Long | Steel wire with Copper ferrules | 200 |

| WCH4-C | 3/8" Wire for Hose 4", 44" Long | Steel wire with Copper ferrules | 200 |

| Stainless Steel | |||

| WCH1-SS | 1/8" Wire for Hose 1/2" to 1 1/4", 20 1/4" Long | Stainless Steel with Copper ferrules | 200 |

| WCH3-SS | 3/16" Wire for Hose 1/2" to 2", 28" Long | Stainless Steel with Copper ferrules | 200 |

| WCH2-SS | 1/4" Wire for Hose 1 1/2" to 3", 38" Long | Stainless Steel with Copper ferrules | 200 |

| WCH4-SS | 3/8" Wire for Hose 4", 44" Long | Stainless Steel with Copper ferrules | 200 |

Eigenschaften

» Made of high strength galvanized steel, copper or stainless steel.

» Highly resistant to rust and corrosion.

» No tools needed - easy to install and remove.

» Hose to hose or hose to tool application.

Usage / Applications

Factory Packages