Cold Rolled Carbon Tool Steel Strip

Aplicaciones

Razor Blades

Saw Blades

Cutters

Needles

Springs

Measures

Bearing Parts

Agricultural Machinery Parts

Chemical Composition (%)

| JIS | SAE | C | Si | Mn | P | S |

| SK2M | 1.10-1.30 | 0.35 | 0.50 | 0.030 | 0.030 | |

| SK3M | 1.00-1.10 | 0.35 | 0.50 | 0.030 | 0.030 | |

| SAE1095 | 0.90-1.03 | 0.15-0.30 | 0.30-0.50 | 0.030 | 0.050 | |

| SK4M | 0.90-1.00 | 0.35 | 0.50 | 0.030 | 0.030 | |

| SAE1086 | 0.80-0.93 | 0.15-0.30 | 0.30-0.50 | 0.030 | 0.030 | |

| SK5M | 0.80-0.90 | 0.35 | 0.50 | 0.030 | 0.030 | |

| SK6M | 0.70-0.80 | 0.35 | 0.50 | 0.030 | 0.030 | |

| SK7M | 0.60-0.70 | 0.35 | 0.50 | 0.030 | 0.030 |

Thickness Tolerance (mm)

Several different grades of thickness allowance― A(standard) and S, SS, and SSS(special)― are available. The thickness is

measured arbitrarily at more than 10 mm from the edge of the steel. When the width is 20 mm or less, the steel is measured in the center portion.

| Grade | A | S | SS | SSS |

| Anchura | Less than 450 | Less than 450 | Less than 400 | Less than 200 |

| Grosor | ||||

| 0.10-0.15 | ±0.010 | ±0.008 | ±0.007 | ±0.006 |

| 0.15-0.25 | ±0.015 | ±0.010 | ±0.008 | ±0.007 |

| 0.25-0.40 | ±0.020 | ±0.015 | ±0.010 | ±0.008 |

| 0.40-0.60 | ±0.025 | ±0.020 | ±0.015 | ±0.010 |

| 0.60-0.90 | ±0.030 | ±0.025 | ±0.020 | ±0.015 |

| 0.90-1.20 | ±0.040 | ±0.030 | ±0.025 | ±0.020 |

| 1.20-1.60 | ±0.050 | ±0.040 | ±0.030 | ±0.025 |

| 1.60-2.10 | ±0.055 | ±0.050 | ±0.040 | ±0.030 |

| 2.10-2.60 | ±0.060 | ±0.055 | ±0.050 | ±0.040 |

| 2.60-3.25 | ±0.065 | ±0.060 | ±0.050 | ±0.045 |

| 3.25-4.00 | ±0.080 | ±0.070 | ±0.060 | ±0.050 |

| 4.00-5.00 | ±0.090 | ±0.080 | ±0.070 | --- |

Width Tolerance (mm)

| Grade | A | S | ||

| Anchura | Less than 200 | Less than 450 | Less than 200 | Less than 450 |

| Grosor | ||||

| <0.60 | ±0.15 | ±0.25 | ±0.10 | ±0.20 |

| 0.60-1.20 | ±0.20 | ±0.30 | ±0.15 | ±0.25 |

| 1.20-3.25 | ±0.25 | ±0.40 | ±0.20 | ±0.35 |

| 3.25-4.00 | ±0.25 | ±0.40 | ±0.20 | ±0.35 |

| 4.00-5.00 | ±0.40 | ±0.55 | ±0.35 | ±0.50 |

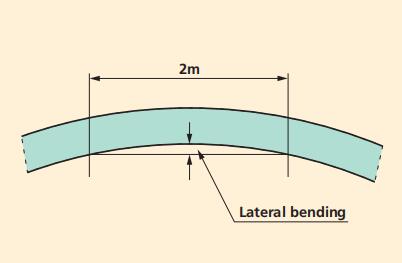

Lateral Bending Tolearance (mm)

| Grade | A | S | SS |

| Anchura | |||

| 10-20 | 20 | 15 | 12 |

| 20-40 | 15 | 10 | 8 |

| 40-80 | 8 | 6 | 4 |

| 80-450 | 4 | 3 | - |

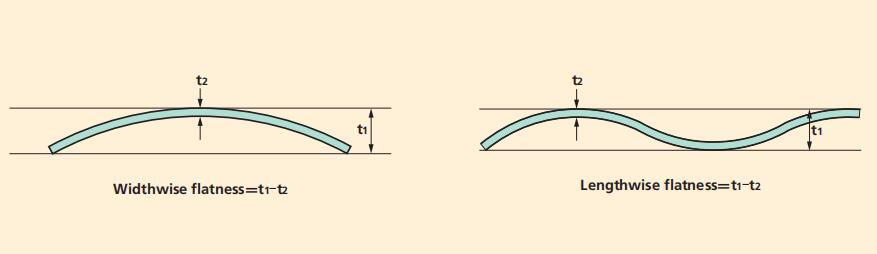

Flatness Tolerance (mm)

| Tolerance | Grosor | |||||

| ≤0.60 | 0.60-1.20 | 1.20-3.20 | 3.20-5.00 | |||

| ≤200 | Annealed | Widthwise | 1.0 | 1.0 | 1.5 | 2.0 |

| Lengthwise | 2.0 | 3.0 | 3.0 | 5.0 | ||

| Hard-drawn | Widthwise | 1.0 | 1.5 | 1.5 | 2.5 | |

| Lengthwise | 3.0 | 4.0 | 4.0 | 6.0 | ||

| 200-450 | Annealed | Widthwise | 1.5 | 2.0 | 2.5 | 3.0 |

| Lengthwise | 4.0 | 5.0 | 5.0 | 7.0 | ||

| Hard-drawn | Widthwise | 1.5 | 2.0 | 3.0 | 4.0 | |

| Lengthwise | 6.0 | 7.0 | 7.0 | 9.0 | ||

Hardness (HV)

| Standard | Type of Steel | Annealing Hardness | Deep-Drawing Hardness | |

| Standard | Special | |||

| JIS | SK2M | 220 | 200 | --- |

| SK3M | 210 | 190 | 210-300 | |

| SK4M | 200 | 180 | 200-280 | |

| SK5M | 180 | 170 | 200-280 | |

| SK6M | 180 | 170 | 180-260 | |

| SK7M | 180 | 160 | 180-260 | |

| SAE | SAE1078 | 180 | 170 | 200-280 |

| SAE1086 | 180 | 170 | 200-280 | |

| SAE1095 | 220 | 190 | 220-280 | |

Heat Treatment

| Type of Steel | Water Hardening | Oil Hardening | ||

| Temperature (°C) | Hardness (HRC) | Temperature (°C) | Hardness (HRC) | |

| SK2M | 760-820 | 62 | 790-850 | 60 |

| SK3M | 760-820 | 62 | 790-850 | 60 |

| SK4M | 760-820 | 62 | 790-850 | 60 |

| SK5M | 760-820 | 62 | 790-850 | 60 |

| SK6M | 760-820 | 62 | 790-850 | 60 |

| SK7M | 760-820 | 59 | 790-850 | 57 |

Terminar

Aside from ordinary annealing and hard-drawn finishes, Volda also implements PPC, PT, and other

finishes aimed at speeding up hardening and conserving heat. Cold-rolled steel strips are available in the following finishes.

| Stage | Symbol | Condition |

| Annealing | A | Annealing is implemented after cold rolling |

| Skinpass | S | Annealing and thermal refining are implemented after cold rolling |

| Deep drawing | C | Cold rolling is implemented |

| Patenting | PT | Patenting treatment and fixed cold rolling are implemented |

| PPC | PC | Spheroidal carbide is refined |