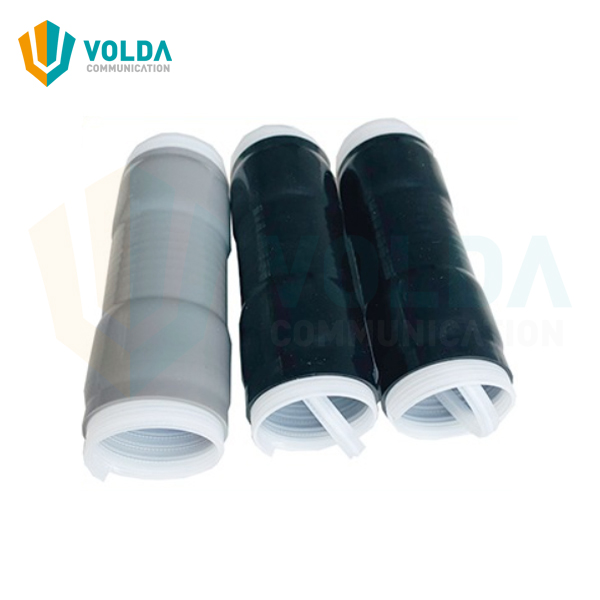

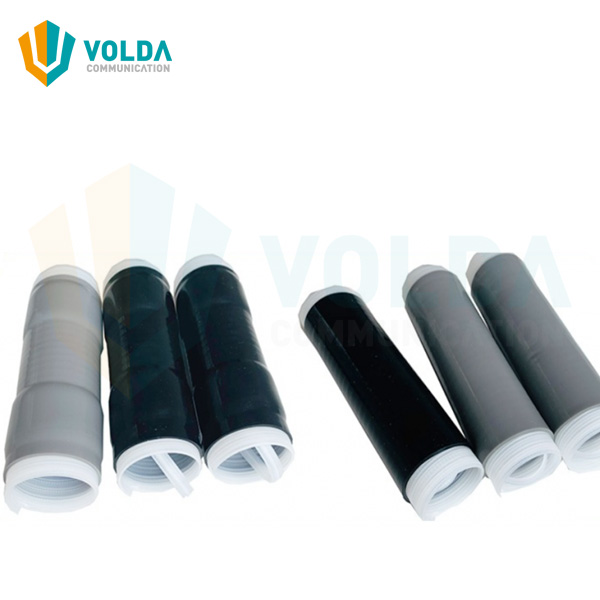

Silicone Cold Shrink Tube with Mastic for Weatherproof

Cold shrink tube is an ideal sealing product for communication cables, coaxial cables, medium and low voltage power cables. Cold shrink tube with mastic built-in is designed for better weatherproof protection on connections between jumper cable and connector (7-16 DIN, N type or 4.3-10) of wireless equipment, such as RRU, Antenna and Microwave.

Caracteristicas

» High elastic silicone rubber tube structure with mastic built-in for better weatherproofing protection;

» Stable and long life during operation;

» Fast installation, only 15-30 seconds needed to seal one connection;

» Perfect SWR performance approved by telecom operators;

» Good operating capability under extreme cold and hot condition, anti-UV, anti-ozone;

» Much time and labor cost saving;

Properties

| Item | Parameter and Result | Test Method | |

| Impermeable | Class | Pass, IPX7 | IEC 60529:1989/AMD2:2013/COR1:2019 1 meter depth in water, duration: 30 minutes |

| Physical and mechanical properties | Shore Hardness | A/41/1 | ASTM D2240-15 |

| Fuerza de Tensión | 9.66 MPa | ASTM D412-16 Method A | |

| Elongation | 930% | ASTM D412-16 Method A | |

| Resistencia al desgarre | 28.4 N/mm | ASTM D624-00 | |

| Brittleness Temperature by Impact | Pasar | ASTM D746-14,-60℃ | |

| Drop Test | Pasar No damage, deformation, and support tube could be pulled out normally | Drop from height 1.2m on tile floor surface, 3 times to test | |

| Flammability | Horizontal Burning | HB | UL 94-2013 Rev.14-2022 Section 7 |

| Electricity | Resistencia dieléctrica | 19.10 KV/mm | ASTM D149-20 Method A |

| Performance under harsh environment | Mechanical and Waterproof Properties | No crack, discoloration, damage or deformation, IPX7 Pass

| 1. Dry heat test (IEC 60068-2-2:2008 Test Bb): 90±2℃,168 hours; 2. Low temperature test (IEC 60068-2-1:2008Test Ab): -40±2℃,168 hours; 3. Thermal cycling test: Cycle time:12h/cycle, Cycle index: 10 cycles, Total duration: 120 hours; 4. Damp heat test, cyclic test (IEC 60068-2-30:2005 Test Db):Cycle time:24h/cycle, Cycle index: 10 cycles, Total duration: 240 hours; 5. Damp heat test, steady state (IEC 60068-2-78:2012 Test Cab):Temperature: 75±2℃, Humidity:(95±1) %RH, Total duration: 1000 hours |

| Aging Test | Light Aging Test-UV Exposure | No crack, discoloration, damage or deformation Grey scale: 4-5 IPX7 Pass | ISO 4892-3:2016Cycle1& ISO 105-A02:1993/Cor.2:2005 Lamp type: UVA-340, 8h UV at (60±3)℃ BPT,0.76W/(m²×nm)@340nm 4h condensation at(50±3)℃ BPT Exposure duration:1000 hours |

| Ozone Aging | No crack, discoloration, damage or deformation, IPX7 Pass | ASTM D1149-16 Method B procedure B1 Temperature: 40±1℃ Ozone concentration:50±5 pphm Exposure duration: 72 hours | |

| Hailstone Resistant Test | No crack,damage or deformation | IEC 61215,φ20mm hailstone falling | |

| Material | Environmental Protection | RoHS Reach | IEC 62321 SVHC |

| Temperatura | Installation Temperature | -40℃ ∼ 60℃ | Refer to “mechanical properties” and “performance under harsh environment” |

| Operation Temperature | -60℃ ∼ 80℃ | ||

| Stock Temperature | -60℃ ∼ 80℃ | ||

Aplicaciones

»Proporciona una excelente protección física y sellado contra la humedad para conectores y cables de telecomunicaciones.

»Aplicación perfecta para conexiones de unidades de radio remotas.

»Reparación de cubiertas y cubiertas de cables.

»Protección contra la corrosión de racores y acoplamientos.

Specification

| Model | Color | Solicitud | Package |

| CSTM125-DIN | Black or Grey | 7-16 DIN connector to 1/2" jumper | 100 pcs/carton |

| CSTM110-4310 | Black or Grey | 4.3-10 or N type connector to 1/2" jumper | 100 pcs/carton |

| CSTM150-1278 | Black or Grey | 7/8" feeder to 1/2" jumper | 100 pcs/carton |