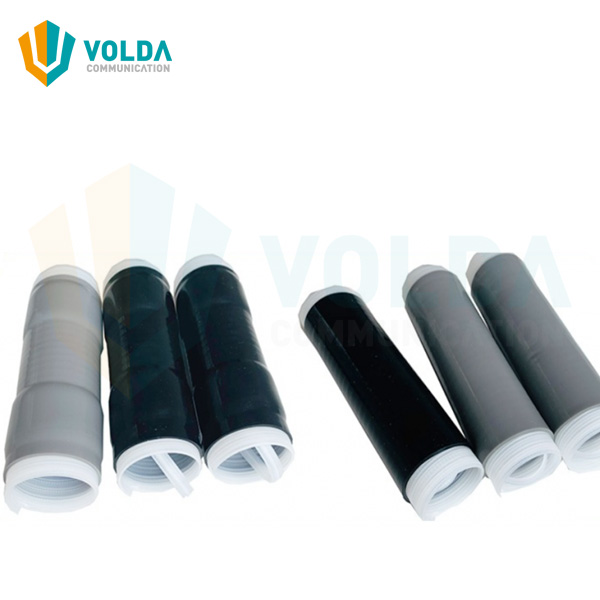

Silicone Cold Shrink Wrap for 9-35mm Connection

Cold shrink wrap is a specially formulated tubular rubber sleeve pre-expanded on a removable plastic cylinder for easy installation. It does not require heat to shrink, you just need to pull the plastic cord, and then the silicone rubber tubing will shrink rapidly and grip around the cable tightly, which will provide a reliable, long-term sealing and protection to the connector.

Caractéristiques

» Easy and quick installation

»Ne nécessite aucun outil ni chaleur

»Fournit une bonne stabilité thermique

»Convient à une large gamme de tailles de câbles

»Excellente résistance à la déchirure

» UV and ozone aging resistant

Note: In certain applications, a foam tape will be needed for smaller cable diameter that cannot be covered with the tube range, the foam tape is used to increase the smaller cable diameter and assure the sealing of clod shrink tube.

Properties

| Item | Parameter and Result | Test Method | |

| Étanche | Class | Pass, IPX7 | IEC 60529:1989/AMD2:2013/COR1:2019 1 meter depth in water, duration: 30 minutes |

| Physical and mechanical properties | Shore Hardness | A/41/1 | ASTM D2240-15 |

| Résistance à la traction | 9.66 MPa | ASTM D412-16 Method A | |

| Elongation | 930% | ASTM D412-16 Method A | |

| La force des larmes | 28.4 N/mm | ASTM D624-00 | |

| Brittleness Temperature by Impact | Passer | ASTM D746-14,-60℃ | |

| Drop Test | Passer No damage, deformation, and support tube could be pulled out normally | Drop from height 1.2m on tile floor surface, 3 times to test | |

| Flammability | Horizontal Burning | HB | UL 94-2013 Rev.14-2022 Section 7 |

| Electricity | Résistance diélectrique | 19.10 KV/mm | ASTM D149-20 Method A |

| Performance under harsh environment | Mechanical and Waterproof Properties | No crack, discoloration, damage or deformation, IPX7 Pass

| 1. Dry heat test (IEC 60068-2-2:2008 Test Bb): 90±2℃,168 hours; 2. Low temperature test (IEC 60068-2-1:2008Test Ab): -40±2℃,168 hours; 3. Thermal cycling test: Cycle time:12h/cycle, Cycle index: 10 cycles, Total duration: 120 hours; 4. Damp heat test, cyclic test (IEC 60068-2-30:2005 Test Db):Cycle time:24h/cycle, Cycle index: 10 cycles, Total duration: 240 hours; 5. Damp heat test, steady state (IEC 60068-2-78:2012 Test Cab):Temperature: 75±2℃, Humidity:(95±1) %RH, Total duration: 1000 hours |

| Aging Test | Light Aging Test-UV Exposure | No crack, discoloration, damage or deformation Grey scale: 4-5 IPX7 Pass | ISO 4892-3:2016Cycle1& ISO 105-A02:1993/Cor.2:2005 Lamp type: UVA-340, 8h UV at (60±3)℃ BPT,0.76W/(m²×nm)@340nm 4h condensation at(50±3)℃ BPT Exposure duration:1000 hours |

| Ozone Aging | No crack, discoloration, damage or deformation, IPX7 Pass | ASTM D1149-16 Method B procedure B1 Temperature: 40±1℃ Ozone concentration:50±5 pphm Exposure duration: 72 hours | |

| Hailstone Resistant Test | No crack,damage or deformation | IEC 61215,φ20mm hailstone falling | |

| Matériel | Environmental Protection | RoHS Reach | IEC 62321 SVHC |

| Température | Installation Temperature | -40℃ ∼ 60℃ | Refer to “mechanical properties” and “performance under harsh environment” |

| Operation Temperature | -60℃ ∼ 80℃ | ||

| Stock Temperature | -60℃ ∼ 80℃ | ||

Applications

»Fournit une excellente protection physique et une excellente étanchéité à l'humidité pour les connecteurs et câbles de télécommunications.

»Application parfaite pour les connexions d'unités radio à distance.

»Réparation des gaines et gaines de câbles.

»Protection anticorrosion des raccords et accouplements.

Information rapide

Product Name: Cold Shrink Wrap

Product Code: CST40-140-9

Matériel: caoutchouc de silicone

Inner Diameter of Plastic Core: 40mm

Diameter (after shrink): 9mm

Length (after shrink): 140mm

Application: Sealing 9-35mm connection

MOQ: 1000

Échantillon offert: gratuit à nos frais

Méthode d'expédition: voie maritime, voie aérienne, DHL, UPS, FedEx, etc.

Port d'expédition: Shanghai, Chine