C67S Spring Steel Strip

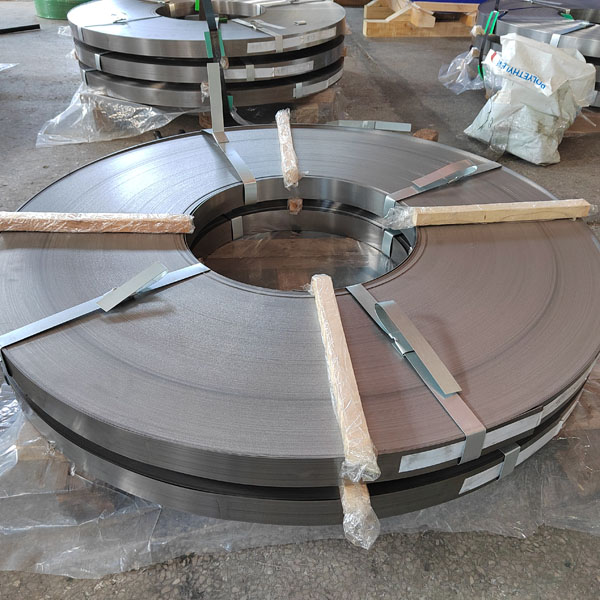

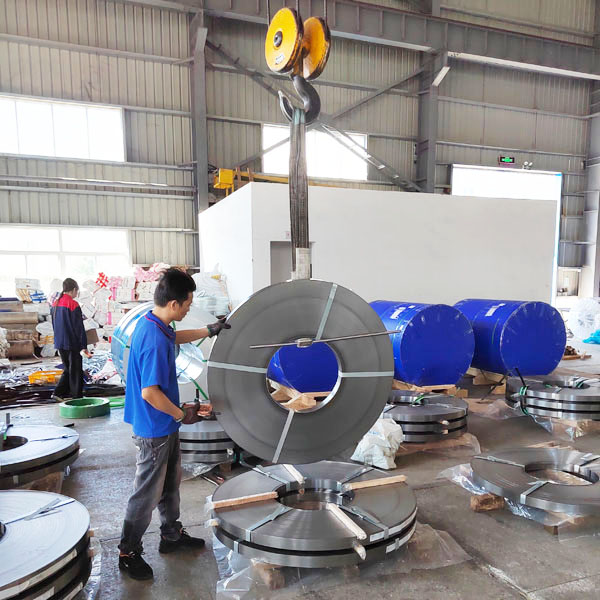

Spring steel strip normally contains between 0.40% to 0.80% carbon, with alloy elements added for the higher integrity products such as automotive clutches etc. Spring steels are quite used in the production of springs, also used in a number of applications where hardness or resistance to bending is required, such as lock parts or tools.

Spring steels are supplied in either annealed condition or hardened and tempered condition. Steel supplied in the annealed condition is usually hardened after the stamping and forming operation in component form. Hardened and tempered strip is more suitable for flat components or where the production is primarily laser cutting or plain blanking.

Chemical Composition:

Carbon: 0.65-0.73%

Silicon: 0.40% max

Manganese: 0.60-0.90%

Phosphorous: 0.025% max

Sulfur: 0.025% max

Chromium: 0.40% max

Molybdenum: 0.10% max

Nickel: 0.40% max

Different values can be discussed with our technicians that will help customers to get better results in their production.

Supply Conditions:

Hardened and tempered (H+T), annealed (A)

Thickness: 0.15-2.50mm

Width: 8.00-300.00mm

Hardness: 29-55HRC

Surface: nature, polished, blue, yellow, black

Edge: slit, sheared, square, rouned